Industrial Hard Chrome

Offers increased life and superior resistance to wear, friction and corrosion because of its excellent lubricity properties.

OUR SERVICES

Electropolish

This process will debur and polish parts to produce a bright finish as well as passivate your parts.

Passivation

The chemical treatment of a stainless steel surface with a mild acid. This is typically done to remove any foreign material from the surface of the metal which enhances the corrosion resistance of the stainless steel surface.

Copper Plating

Copper plating is valued for its versatility, electrical conductivity, and timeless aesthetic appeal, making it ideal for a wide array of applications.

Phosphate Coating

With advanced processing capabilities, we offer both zinc and manganese phosphate coatings, ensuring optimal performance for lubrication, corrosion prevention, and aesthetic enhancement.

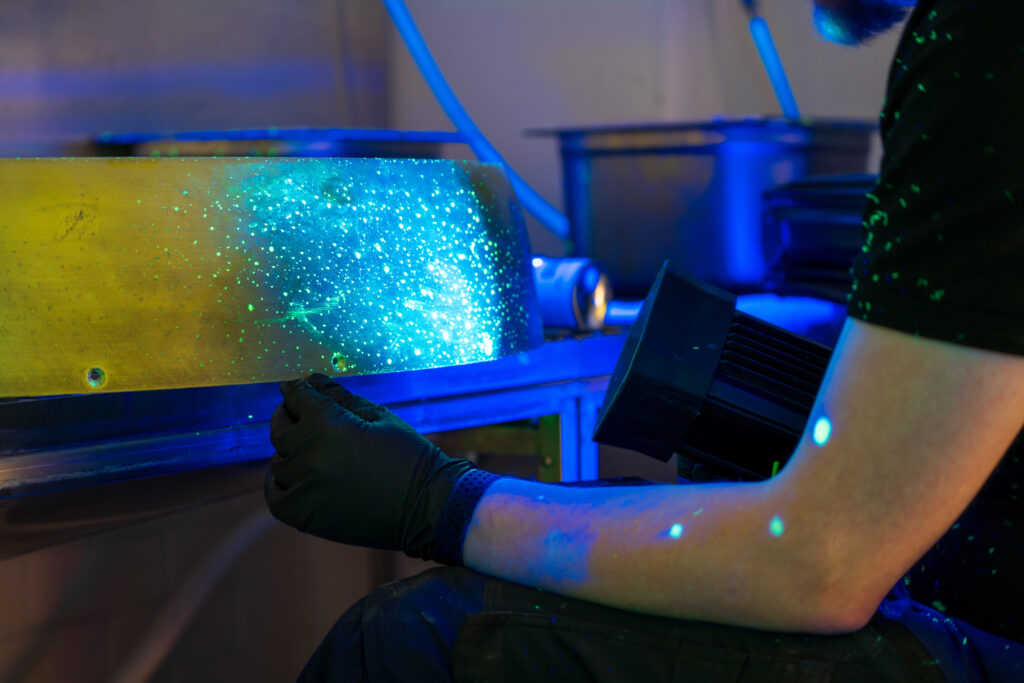

Non-Destructive Testing

Our advanced NDT processes identify defects, discontinuities, and structural weaknesses in metal components without compromising their integrity, ensuring safety, durability, and performance

Silver Plating

Is best suited for engineering purposes for solderable surfaces, electrical contact characteristics, high electrical and thermal conductivity, thermocompression bonding, and other applications. Good corrosion resistance, good solderability.

Sulfamate Nickel Plating

Sulfamate Nickel is renowned for its impressive corrosion resistance, making it the perfect choice for applications where protecting against rust and wear is critical.

Shot Peening

A controlled surface treatment used to increase wear resistance, prevent cracking, and extend the lifespan of metal parts by introducing beneficial compressive stresses.

Bead Blasting

Is a great way to remove surface contaminants and rust from parts before plating and ensures proper cleaning and preparation. It also gives the metal a fine texture that allows the plating to adhere the base metal.

Black Oxide

Provides enhanced corrosion protection and aesthetic appeal. It is a chemical process used as a rust inhibitor for the underlaying metal.

Tin Plating

Our advanced tin plating process ensures a uniform, pore-free coating that enhances component reliability while preventing oxidation, galling, and surface degradation

Cadmium Plating

Is applied to a base metal to provide excellenct resistance to corrosion in most marine and alkaline enviroments. Cadmium also acts as a sacrificial protection to the underlaying metal by being preferentially corroded when damaged.

Electroless Nickel

A high corrosion resistance process designed to produce semi-bright deposits for engineering applications where uniformity of coating is important.

Triple Chrome Plating

Triple Chrome Plating, an exceptional multi-layer plating process that provides superior corrosion resistance, unmatched durability, and a flawless mirror-like finish.